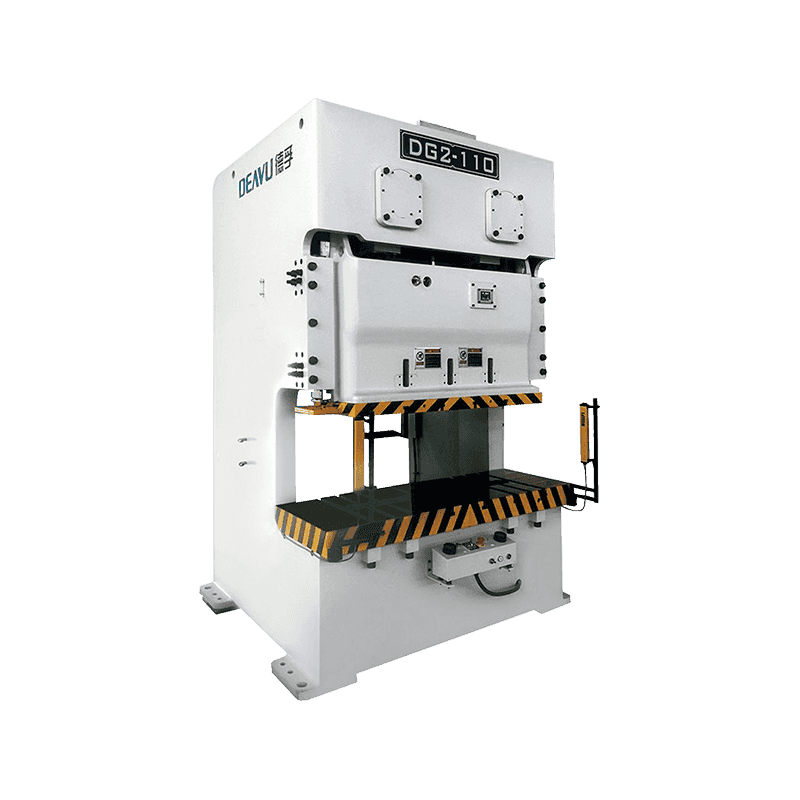

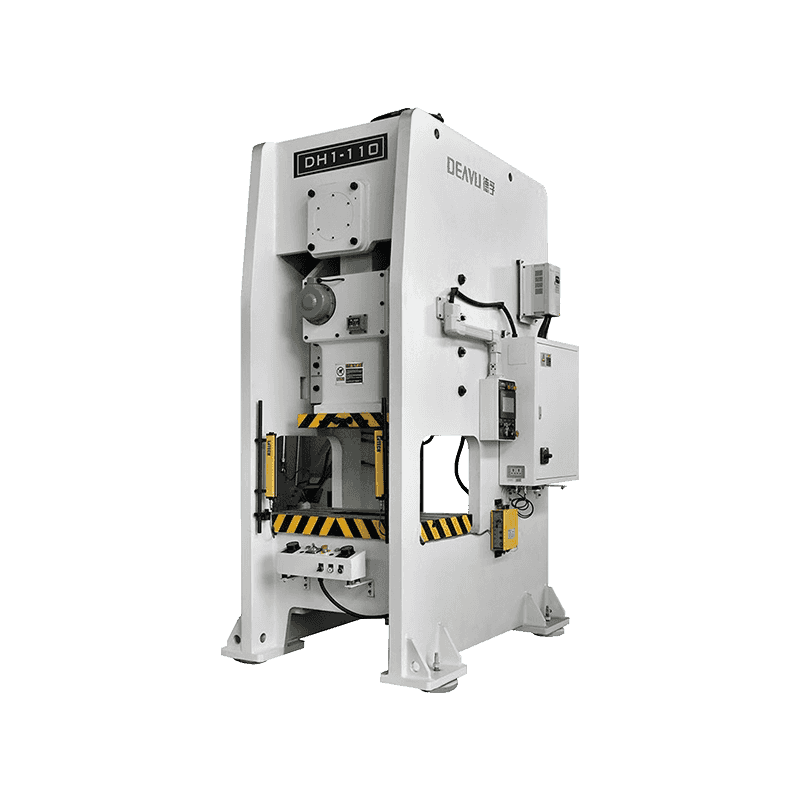

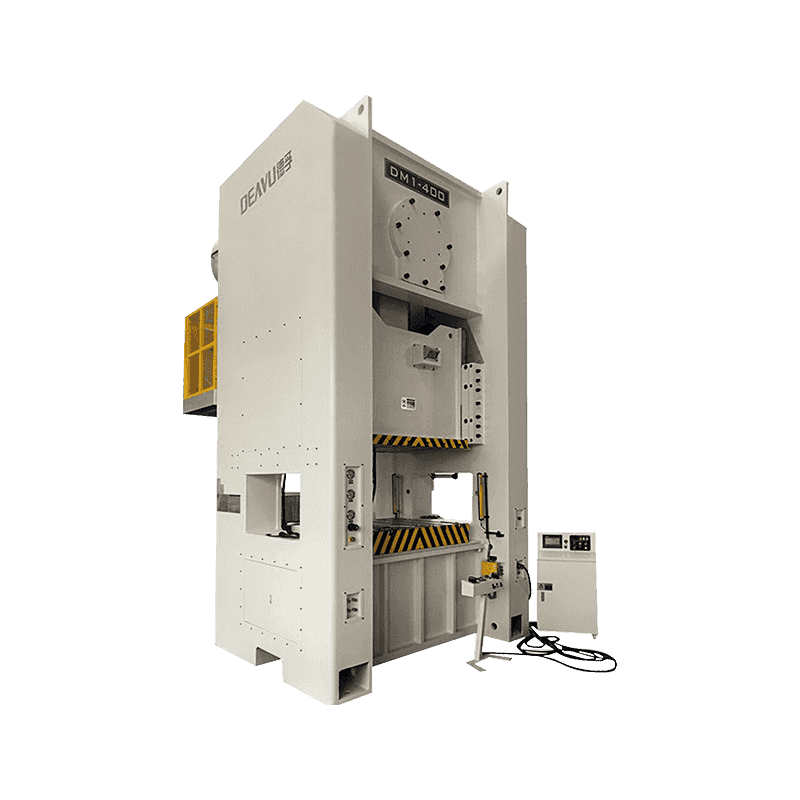

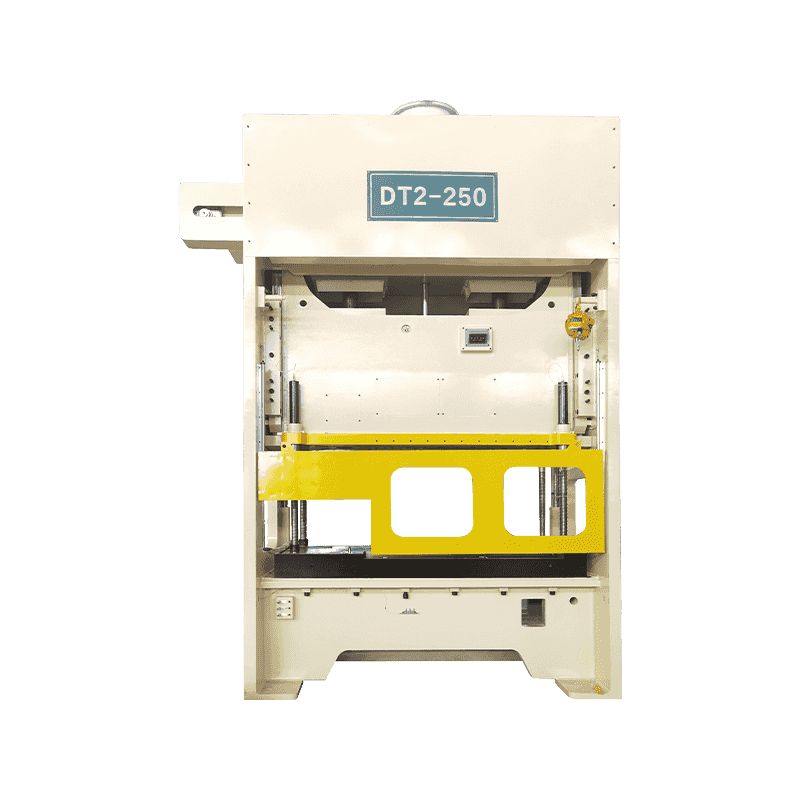

The Punch Press Machine is a versatile and essential piece of equipment in many industries today. With its ability to deliver high precision and efficiency in a variety of tasks, the Punch Press Machine plays a critical role in shaping and forming materials such as metal, plastic, and other materials. These machines, typically used for punching, blanking, forming, and shearing, have broad applications across industries like automotive, aerospace, electronics, and construction.

Automotive Industry

The automotive industry is one of the significant users of Punch Press Machines. Manufacturers in this sector rely heavily on the high-speed, precision capabilities of these machines for producing various metal components used in vehicles. From body panels and chassis parts to brackets and mounting points, a Punch Press Machine is integral to the mass production of automotive components.

A Punch Press Machine Manufacturer supplies specialized machines that can handle the complex requirements of automotive production. These machines can punch out intricate designs, such as holes for screws, bolts, and other fastening mechanisms, which are essential for assembling vehicles. By using a Punch Press Machine, automotive manufacturers can ensure uniformity and consistency in the parts, which is crucial for vehicle safety and performance.

Metal Fabrication

In the metal fabrication industry, Punch Press Machines are indispensable tools used to shape and cut metal sheets. The ability to punch precise holes and shapes allows manufacturers to produce parts used in construction, industrial equipment, and structural components.

A Punch Press Machine Manufacturer often provides machines capable of handling various types of metals, including steel, aluminum, and copper. The machine's versatility ensures that it can be used for producing everything from basic sheet metal panels to more complex components, like perforated panels or customized metal forms. The consistent output quality and high throughput make Punch Press Machines highly valued in the fabrication sector.

Electronics Industry

The electronics industry also benefits from the precision of Punch Press Machines. These machines are commonly used to create parts for electrical components, such as circuit boards, connectors, and enclosures. The Punch Press Machine Manufacturer offers machines that can work with delicate materials and components to produce small, accurate cuts and holes without damaging sensitive electronics.

In the production of electronic enclosures, a Punch Press Machine is often used to create vents, holes for connectors, or even intricate patterns to facilitate heat dissipation. The speed and accuracy of these machines enable electronics manufacturers to produce high volumes of components with minimal waste, which is crucial for keeping production costs low.

Aerospace Industry

The aerospace industry requires parts with very tight tolerances and exceptional strength. Punch Press Machines are used extensively to manufacture components for aircraft and spacecraft, such as brackets, panels, and other structural components. The precision of these machines ensures that each part meets stringent quality standards while maintaining the necessary mechanical properties.

A Punch Press Machine Manufacturer produces machines capable of working with high-strength materials like titanium and specialized alloys, which are commonly used in the aerospace sector. The machines are also capable of executing highly intricate punching patterns, such as those required for aircraft panels that must balance strength and weight considerations.

EN

EN