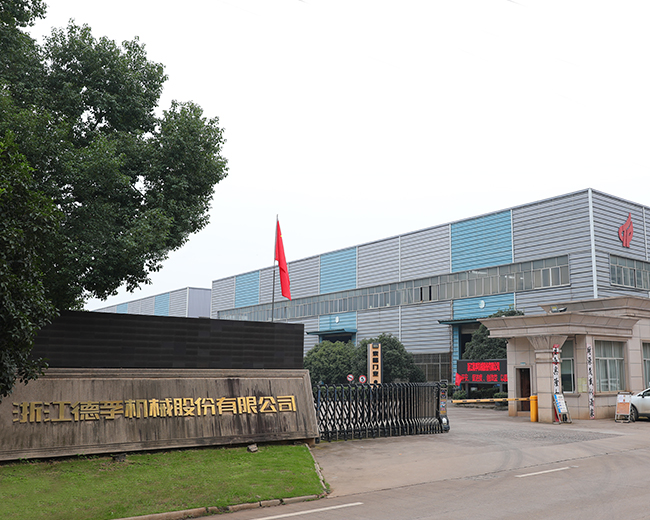

WELCOME TO DEFU!

The company mainly produces various types of hydraulic presses, various four-column and gantry hydraulic presses with dozens of specifications, hundreds of varieties of hydraulic and forging equipment, as well as open, closed, single-point, double-point, and four-point precision punching equipment and products. It is suitable for many industries and fields such as automobiles, aerospace, nuclear power, ships, home appliances, communications, etc. The company's products have always been recognized by domestic and foreign customers for their exquisite design, reasonable prices, quality, fast after-sales service, and technical support. They are sold well in more than 30 domestic provinces, cities, and districts, and are exported to the United States, Europe, and Southeast Asia. , the Middle East, Africa, and other regions and dozens of countries. The company pays attention to scientific and technological progress and has built a technology center that is suitable for its development. It has a scientific research team of dozens of people with reasonable structure, completely professional and rich experience, and strong independent research and development capabilities.

Latest News

Essential Accessories for Power Punch Press Machinery

Power punch press machinery is a cornerstone of the metalworking industry, providing the force and precision needed to shape, cut, and form metal components. However, the efficiency and versatility of these machines are significantly enhanced by a variety of accessories. Understanding these Punch Power Press Machinery Accessories is crucial for optimizing the performance and productivity of power punch press machinery. Here, we explore some of the main accessories that support and augment the functionality of power punch press machines.

Die Sets

Die sets are fundamental Punch Power Press Machinery Accessories. These sets consist of upper and lower dies, which come together to shape or cut the metal workpiece. Die sets are tailored to specific tasks, such as blanking, bending, or embossing, and are made from high-grade steel to withstand the high pressures exerted during operations. The precision and quality of the die set directly impact the accuracy and finish of the final product.

Punches and Punch Holders

Punches are the components that make contact with the metal workpiece, exerting force to create holes or shapes. They are typically made from high-strength materials to endure the wear and tear of repeated use. Punch holders, on the other hand, secure the punches in place and ensure their proper alignment. Together, punches and punch holders are essential for achieving precise and consistent results in punching operations.

Stripper Plates

Stripper plates play a crucial role in the punch press process by helping to remove the workpiece from the punch after the operation is complete. These plates ensure that the metal piece is cleanly and efficiently separated from the punch, preventing any damage or deformation. Stripper plates are designed to withstand significant force and are often adjustable to accommodate different workpiece thicknesses.

Knockout Pins

Knockout pins, also known as ejector pins, are used to push the finished workpiece out of the die set after the forming process. These pins ensure that the workpiece is cleanly ejected without damage, allowing for smooth and continuous operation of the punch press. Knockout pins are designed to be durable and reliable, withstanding repeated use without bending or breaking.

Automatic Feeders

Automatic feeders are Punch Power Press Machinery Accessories that significantly enhance the productivity of power punch press machines by automating the feeding of material into the press. These feeders can handle a variety of materials, including sheets, coils, and strips, and ensure a consistent and precise feed rate. By automating the feeding process, automatic feeders reduce downtime and increase the overall efficiency of the punch press operation.

Lubrication Systems

Proper lubrication is essential for the smooth and efficient operation of power punch press machinery. Lubrication systems ensure that all moving parts are adequately lubricated, reducing friction and wear. These systems can be automated to provide continuous lubrication during operation, thereby extending the lifespan of the machinery and maintaining performance. Regular maintenance and monitoring of the lubrication system are critical to prevent breakdowns and ensure consistent quality in the punching process.

Safety Guards and Light Curtains

Safety is paramount in any manufacturing environment, and power punch presses are no exception. Safety guards and light curtains are essential accessories designed to protect operators from injury. Safety guards are physical barriers that prevent access to dangerous parts of the machine, while light curtains use infrared beams to detect the presence of an operator's hand or arm. If the light beam is broken, the machine will automatically stop, preventing accidents. These safety features are crucial for creating a safe working environment and complying with regulatory standards.

Control Panels and Programmable Logic Controllers (PLCs)

Modern power punch press machines are often equipped with advanced control panels and programmable logic controllers (PLCs). These accessories allow operators to set and adjust machine parameters with precision, ensuring consistent and repeatable results. PLCs can automate various aspects of the punch press operation, including feed rates, punching cycles, and safety protocols. This automation enhances the accuracy and efficiency of the machinery, making it easier to produce high-quality parts with minimal manual intervention.

Workpiece Positioning Systems

Accurate positioning of the workpiece is crucial for achieving precise results in punching operations. Workpiece positioning systems, such as CNC tables or mechanical stops, ensure that the material is correctly aligned and held in place during the punching process. These systems can be manually adjusted or fully automated, depending on the requirements of the operation. By ensuring accurate positioning, these Punch Power Press Machinery Accessories help to reduce errors and improve the overall quality of the finished product.

EN

EN