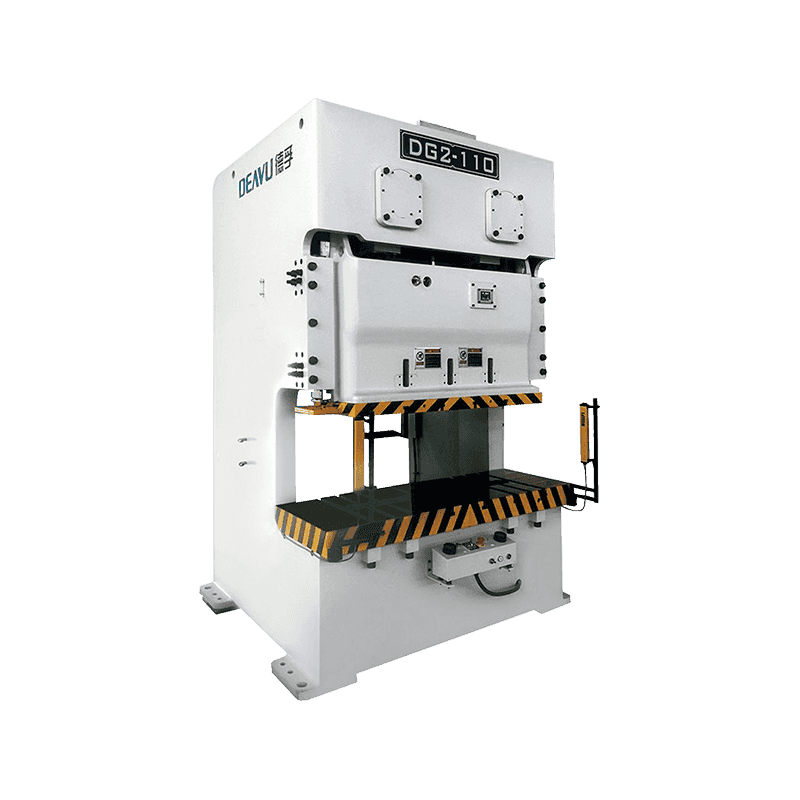

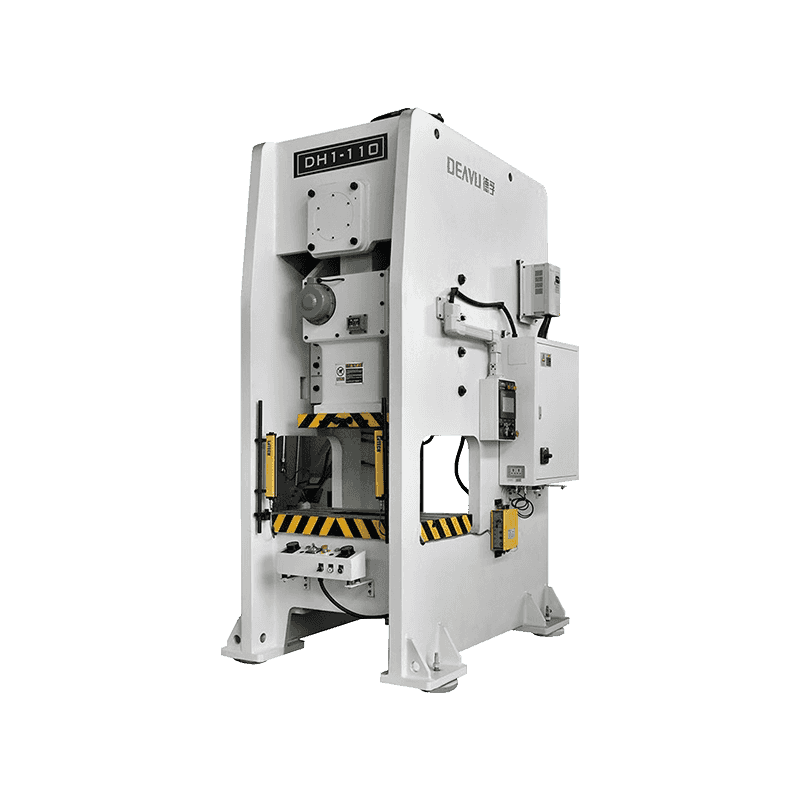

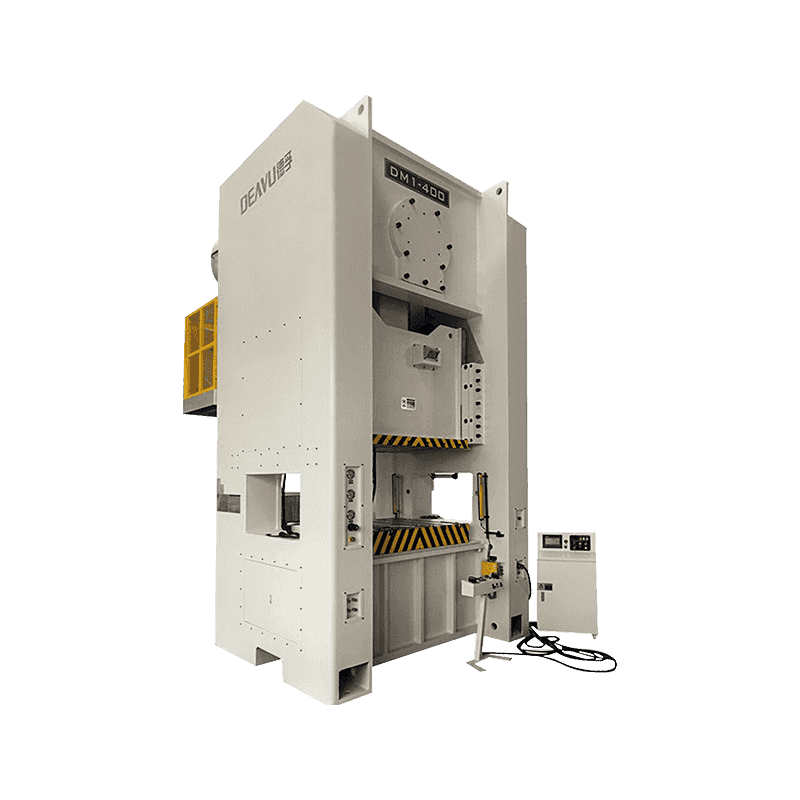

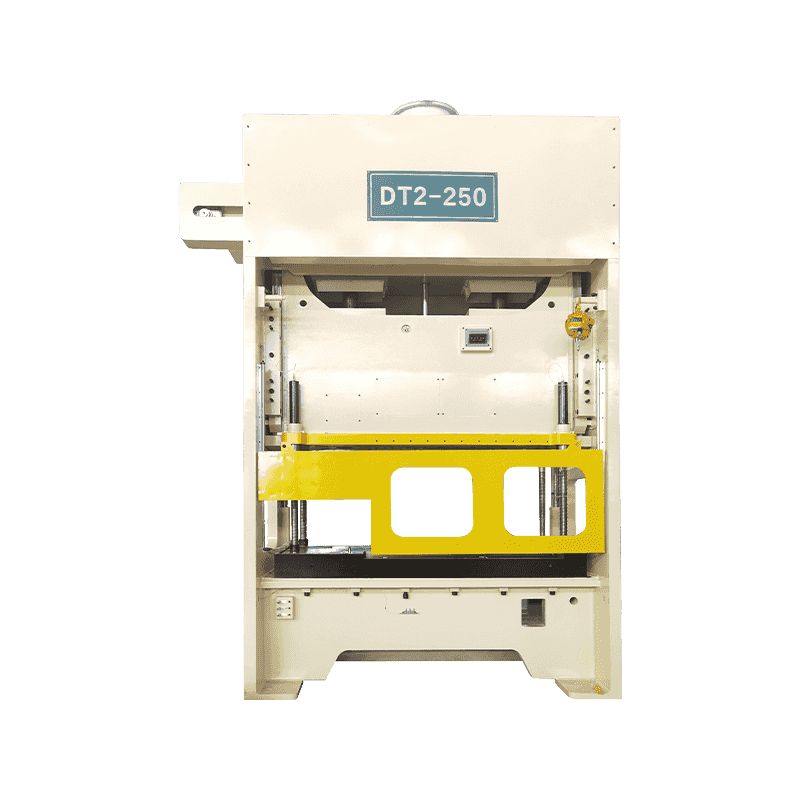

The CNC Punching Machine has become an essential tool in modern manufacturing processes. Its ability to perform high-speed and accurate operations makes it highly valuable in industries such as automotive, aerospace, metal fabrication, and more. CNC, which stands for Computer Numerical Control, allows for the automation of the punching process, improving both precision and efficiency.

One of the significant advantages of a CNC Punching Machine is its exceptional precision. Traditional punching machines required manual adjustments and were limited in terms of accuracy. However, with the advent of CNC technology, punching machines can now execute precise movements and punches that are programmed with high accuracy.

The machine is controlled by a computer program that dictates the exact position, angle, and force of each punch. This ensures that each part is manufactured to the exact specifications, eliminating human error and reducing variations in production. The high level of precision makes CNC punching ideal for industries where accuracy is critical, such as in the manufacturing of metal parts for the automotive and aerospace industries.

The CNC Punching Machine offers a significant increase in productivity compared to traditional manual punching methods. This is because CNC machines can operate continuously, performing multiple tasks without the need for frequent human intervention.

CNC punching machines are equipped with automated tools and the ability to perform multiple punching operations on a single sheet of material, significantly reducing cycle times. The ability to process large quantities of materials in a shorter amount of time helps manufacturers meet tight deadlines and increase overall production output. This level of automation ensures that manufacturing processes are completed faster and with fewer labor hours, which bring about cost savings.

Another important advantage of a CNC Punching Machine is its ability to handle a wide range of materials. Whether it's sheet metal, plastic, or other materials, the CNC punching machine can punch, shape, and process them efficiently. The versatility of the machine makes it suitable for different industries and applications.

The CNC Punching Machine can be adjusted to punch different thicknesses of material and can handle a wide array of sizes. This flexibility allows manufacturers to produce custom parts that meet specific requirements for a variety of applications, from small components to large industrial parts. As a result, businesses can streamline their operations and offer a wider range of products.

While the initial investment in a CNC Punching Machine might be higher compared to manual or less automated punching systems, the long-term benefits far outweigh the initial cost. CNC machines require fewer operators, reducing labor costs, and they also help to minimize material waste.

The precision of a CNC Punching Machine ensures that materials are used efficiently, and parts are punched with minimal scrap. This not only reduces costs but also helps with sustainability by material waste, which is an important factor in modern manufacturing. Moreover, since the machine can work for extended periods without needing frequent maintenance, the operational costs remain low.

EN

EN