Metallic processing machinery manufacturer plays a vital role in modern manufacturing, construction, and various industrial sectors. These machines are designed to shape, cut, form, join, and finish metal materials, enabling the production of components, tools, and structures essential for countless applications. Understanding the range and functions of metallic processing machinery is important for industries aiming to optimize production efficiency, improve product quality, and maintain cost-effectiveness.

Metallic processing machinery refers to the broad category of equipment used to manipulate metal raw materials into desired shapes, sizes, and properties. The machinery is often classified based on the specific process they perform, such as cutting, shaping, joining, or finishing.

These machines can be manually operated, semi-automated, or fully automated with computer numerical control (CNC) systems, depending on the complexity and precision required. The diversity of metallic processing machinery reflects the vast range of metals and alloys, as well as the varied industrial needs.

Cutting machinery is designed to remove unwanted metal from a workpiece to achieve the desired shape or size. Common cutting processes include sawing, shearing, laser cutting, water jet cutting, and plasma cutting.

Metal Shearing Machines: These use a blade to slice metal sheets or plates with straight or curved cuts. They are widely used for initial shaping of sheet metals.

Laser Cutting Machines: Employ focused laser beams to precisely cut metals with minimal heat-affected zones. Ideal for complex patterns and fine details.

Plasma Cutters: Utilize a plasma torch to cut through thick metal plates quickly, commonly used in heavy fabrication industries.

Water Jet Cutters: Use high-pressure water mixed with abrasive materials to cut metals without generating heat, suitable for heat-sensitive metals.

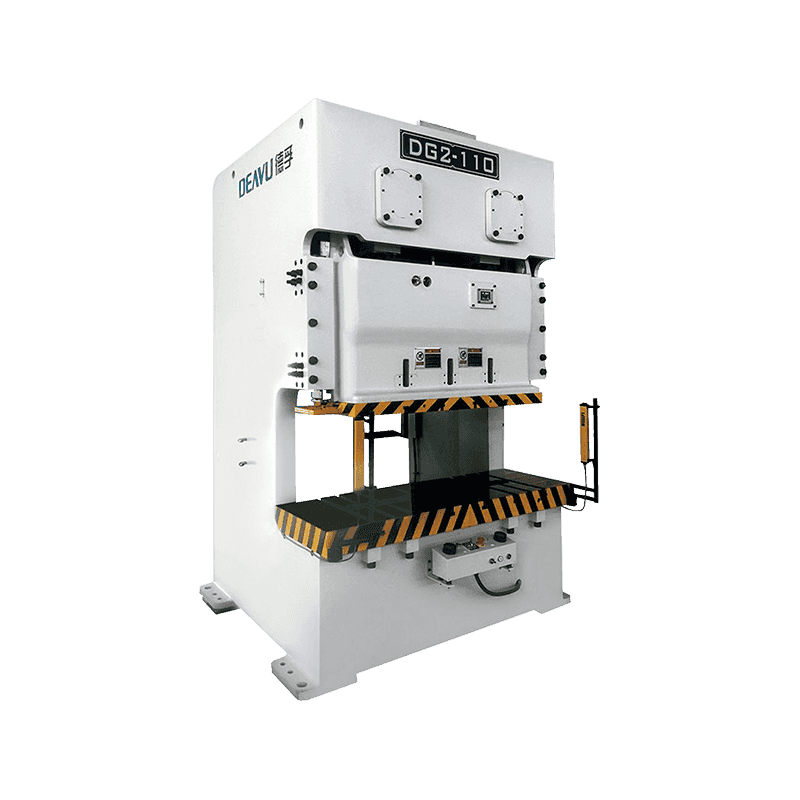

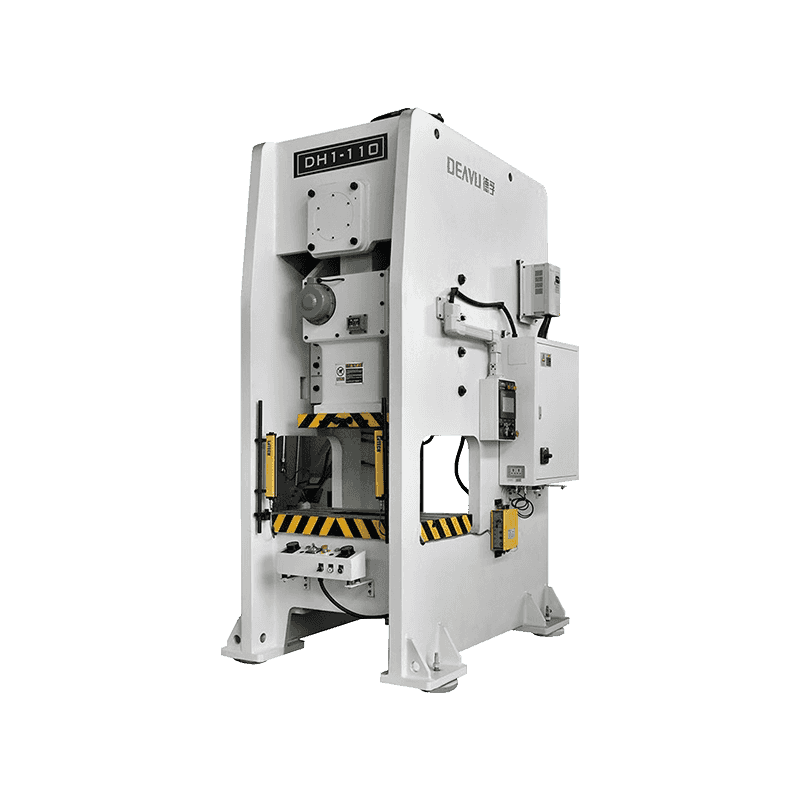

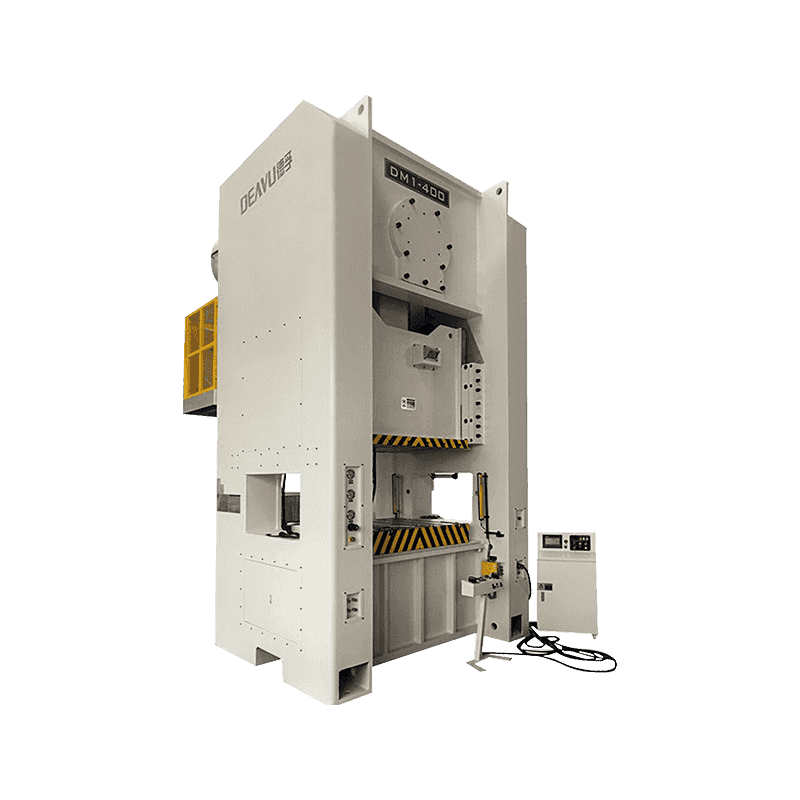

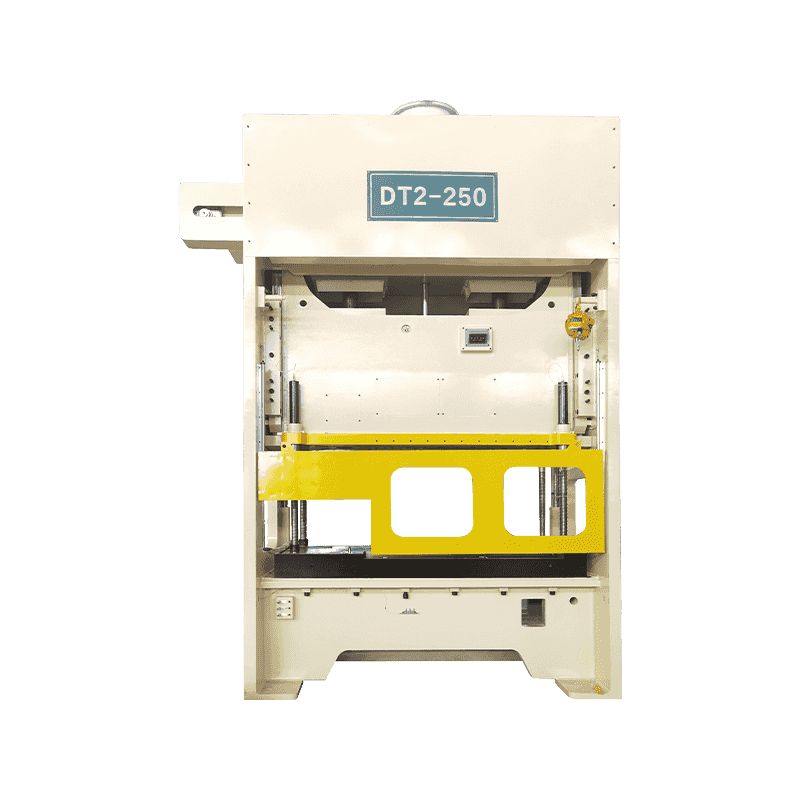

Forming machinery modifies the shape of metals without removing material, often by applying mechanical force. This category includes machines used for bending, rolling, forging, stamping, and extrusion.

Press Brakes: Used to bend metal sheets into angles or curves through a pressurized punch and die setup.

Rolling Machines: These machines pass metal sheets or bars through rollers to reduce thickness or produce uniform shapes such as sheets, plates, or structural profiles.

Forging Machines: Apply compressive force to metal billets to form desired shapes, improving mechanical properties through grain refinement.

Stamping Presses: Used to cut and form metal sheets in a single operation, often producing parts for automotive and appliance industries.

Extrusion Machines: Force heated metal through a shaped die to create long objects with consistent cross-sections such as pipes, rods, and channels.

Machining equipment precisely removes metal by cutting tools to achieve tight tolerances and fine surface finishes. This includes lathes, milling machines, drilling machines, and grinding machines.

Lathes: Rotate the workpiece against a cutting tool to produce cylindrical or conical parts, used extensively for shafts, screws, and bolts.

Milling Machines: Remove metal using rotating cutters, enabling the production of flat surfaces, slots, and complex shapes.

Drilling Machines: Create round holes in metal parts, with variations including radial, pillar, and CNC drilling.

Grinding Machines: Employ abrasive wheels to achieve fine surface finishes or precise dimensions, important for finishing and tool sharpening.

Joining machinery is essential for assembling metal components into final products. Techniques include welding, soldering, brazing, and fastening.

Welding Machines: Use heat or pressure to fuse metals together, with common types including arc welding, MIG welding, TIG welding, and spot welding.

Soldering and Brazing Equipment: Join metals using a filler material with a lower melting point than the base metals, often used for delicate or thin components.

Mechanical Fastening Tools: Such as riveters, bolt tensioners, and presses, used to physically join parts without melting.

Surface treatment machines enhance metal appearance, corrosion resistance, and mechanical properties. Processes include polishing, plating, coating, and heat treatment.

Polishing and Buffing Machines: Remove surface imperfections and improve shine using abrasives or polishing compounds.

Plating Equipment: Apply metal coatings such as chrome or zinc for corrosion resistance and aesthetic enhancement.

Heat Treatment Furnaces: Control temperature cycles to alter metal hardness, toughness, and ductility.

EN

EN