High Precision Strong Steel Frame Punching Machine Supplier

A High Precision Strong Steel Frame Punching Machine is an essential tool in the manufacturing industry, particularly in sectors where high-quality and efficient metalworking is required. These machines are designed to perform various punching, cutting, and forming operations with accuracy and reliability. The robust construction, precision engineering, and advanced features of these machines make them a popular choice for applications in automotive, aerospace, electronics, and metalworking industries.

1. High Precision and Accuracy

One of the important features of a High Precision Strong Steel Frame Punching Machine is its ability to deliver high levels of precision and accuracy in its operations. This machine is engineered to ensure that each punch, cut, or form is executed with accuracy, reducing the margin for error. This level of precision is especially critical when working with materials that require tight tolerances, such as in the automotive or aerospace industries.

The high precision of the machine is achieved through its advanced control systems and carefully engineered components. With advanced CNC (Computer Numerical Control) systems, the machine is able to follow exact specifications and repeat the same operation with consistent results. This minimizes the chances of defects, ensuring that every part produced meets the required standards.

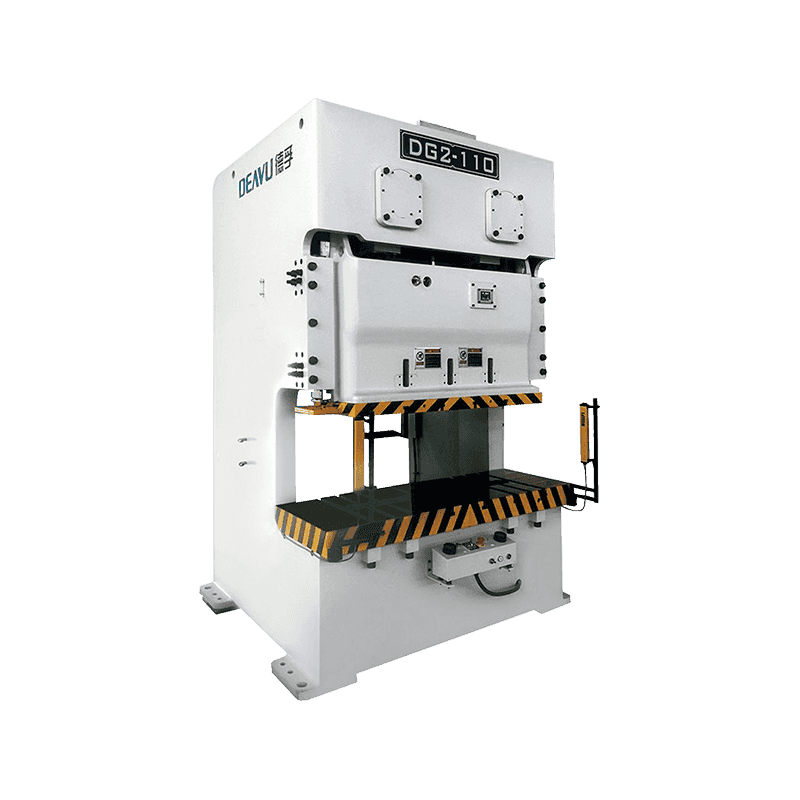

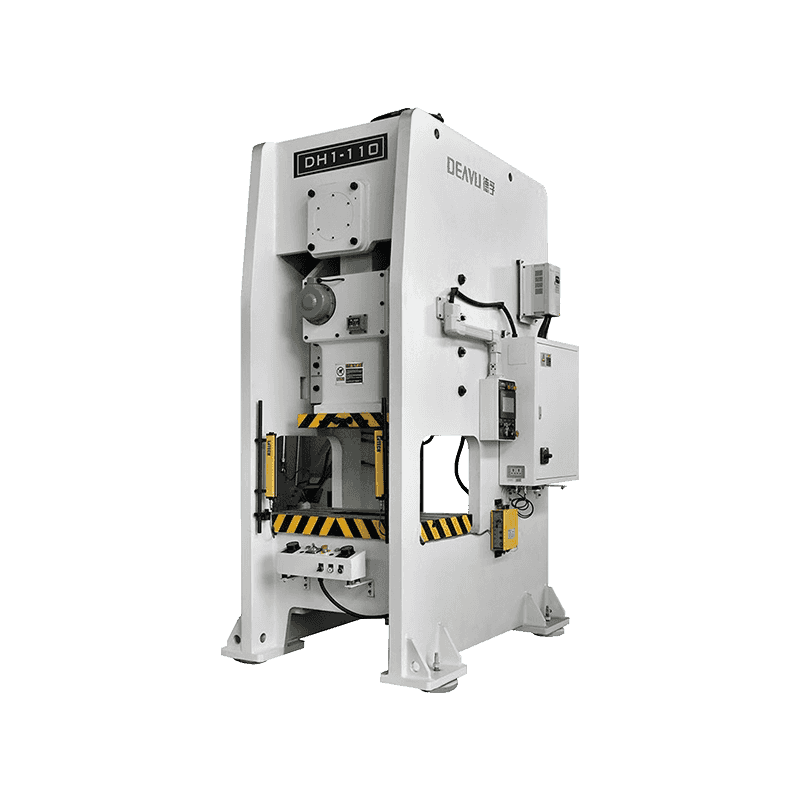

2. Strong Steel Frame for Durability

As the name suggests, a High Precision Strong Steel Frame Punching Machine is built with a robust steel frame that provides exceptional durability and strength. The steel frame is designed to withstand the high forces generated during punching operations, ensuring that the machine maintains its structural integrity even under heavy loads. This strong steel frame not only improves the longevity of the machine but also contributes to the stability of the punching process.

The durability of the steel frame also helps in reducing vibrations during operation, which can affect the accuracy of the punch. By absorbing and dissipating these forces, the frame ensures that the machine operates smoothly and consistently, maintaining the precision of each punch.

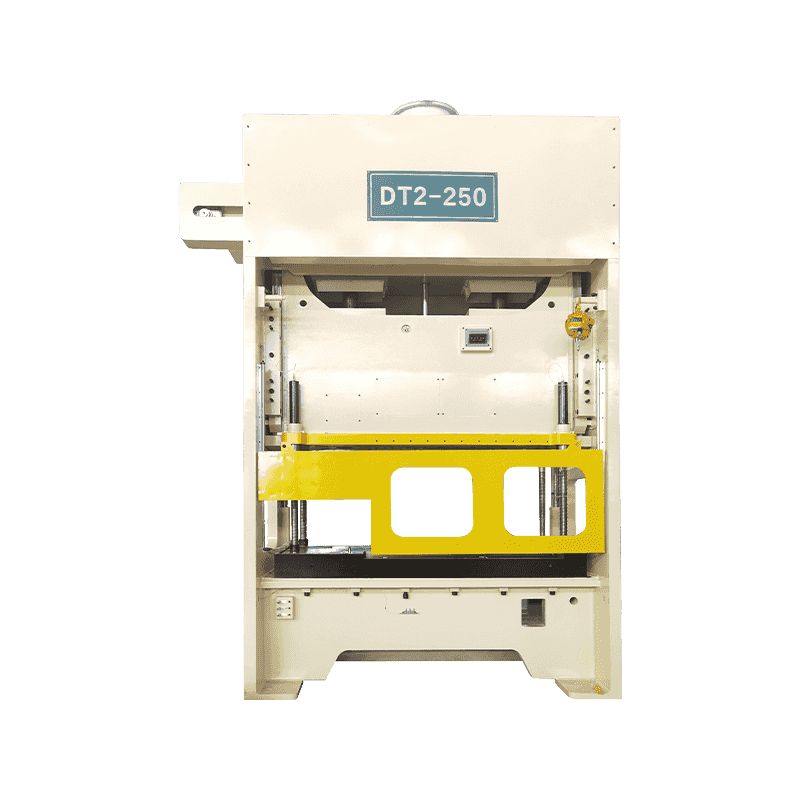

3. Versatility in Operation

The versatility of the High Precision Strong Steel Frame Punching Machine is another key feature that makes it an invaluable asset in various industries. This machine is capable of performing a wide range of punching, cutting, and forming operations on different types of materials, including metals, plastics, and composites. It can be used for tasks such as hole punching, perforating, and embossing, among others.

The versatility of the machine is further enhanced by its ability to accommodate different die sets and tooling, allowing it to handle a variety of tasks with ease. This flexibility makes it suitable for use in industries that require diverse manufacturing processes, as the machine can be easily adapted to different production needs.

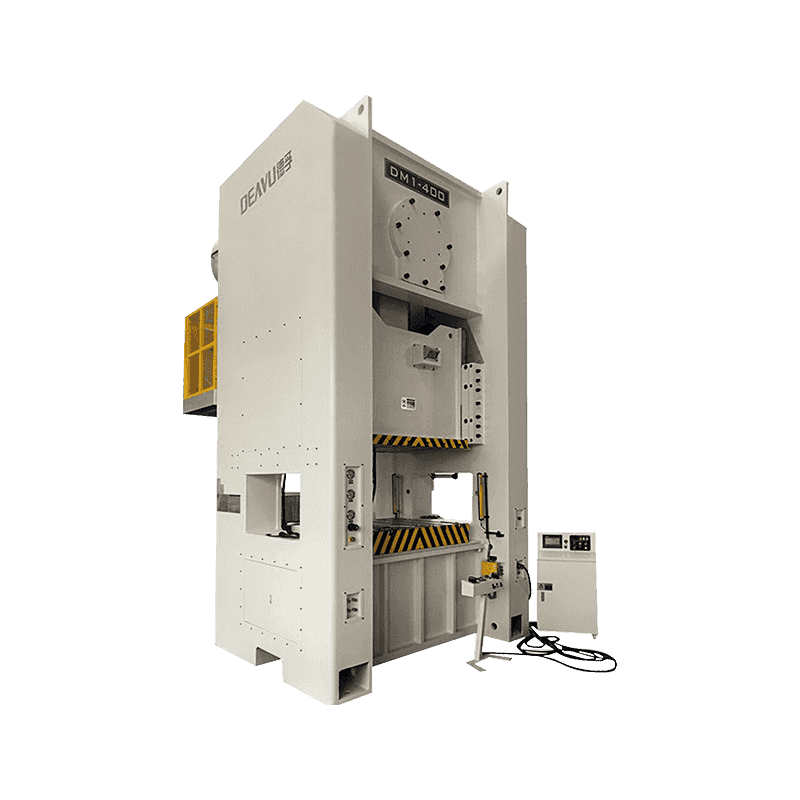

4. High-Speed Operation

Speed is another important feature of the High Precision Strong Steel Frame Punching Machine. These machines are designed to operate at high speeds, enabling manufacturers to meet the demands of high-volume production. With fast cycle times, the machine can perform numerous punching operations in a short period, improving overall productivity and reducing the cost per part.

The high-speed operation is achieved through the use of advanced servo motors and high-quality components that allow for quick and efficient movement of the punching head. This ensures that the machine can complete tasks quickly without compromising on accuracy or quality.

EN

EN